Dr. George Liang, Representative of GauTure Enterprises, attended the "Digitization of Grain Industry" forum

发布日期:2020-10-21 浏览次数:505

On the morning of October 20, during the Third Grain Trade Conference of China, the Grain Industry Digitalization Forum was held at the same time in the Strait International Conference Center in Fuzhou, which was sponsored by the China Information Association and undertaken by the Grain and Agriculture Information Branch of the China Information Association, and GauTure participated in this forum as a co-organizer.

This forum focuses on the application of digital informatization technology of quality grain project, makes a discussion on the achievements of digital informatization construction of good grain and oil, big data acquisition and analysis of grain quality guarantee, interprets all-round digitization to promote the products, technology, market and management of the grain industry, and thematically discusses the hotspots and focuses of the opportunities and challenges of the post-epidemic era, and the socialized service of the whole grain industry chain and its demands.

Dr. George Liang, CTO of GauTure, attended the forum and delivered a keynote speech on "Grain Quality Inspection in the Era of AI and Big Data".

GauTure CTO: Dr. George Liang

After a brief self-introduction and company profile, Dr. Liang began by stating that Big Data, Cloud Computing and Artificial Intelligence are rapidly driving industrial change, and that AI technology represented by machine vision and speech recognition has made significant progress, and that this technological change is penetrating into various fields, from the detection of all kinds of defects on the industrial assembly line to the identification of pests and diseases in the field of agriculture and so on.

Next, Dr. Liang analyzed the current situation of China's grain industry and emphasized that food security not only requires guaranteeing the quantity of production, but also the quality of grain. The white paper "China's Food Security" points out: establish and improve the grain quality and safety inspection and monitoring system composed of grain quality inspection institutions at national, provincial, municipal and county levels, basically realizing "a network of institutions, full coverage of monitoring, and no blind spot in supervision". At present, China's grain quality inspection is characterized by a large number of quality indicators, a large demand for testing and high efficiency requirements.

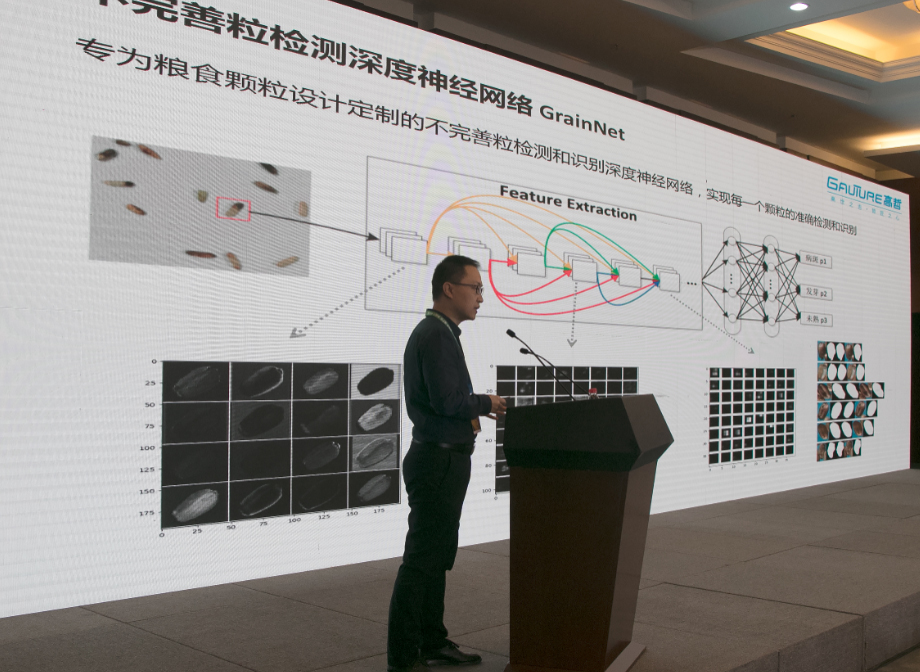

Dr. Liang talked about the imperfect grain detection, which is an important part of grading and grading in grain storage, and is related to grain storage safety and food production safety. At this stage, most of the indicators of grain inspection have been automated and intelligentized, but the detection of imperfect grains still relies on manual work, which is mainly based on human senses such as vision and touch, with poor repeatability, strong subjectivity, large errors, time-consuming and low efficiency. Therefore, realizing the full automation of grain quality inspection is an important goal to promote the development of grain farming and ensure food security.

Dr. George Liang elaborates on grain quality control

Aiming at this industry pain point, Dr. Liang focused on introducing GauTure's research and development achievements over the past few years - GauTure AI fast tester. The fast tester is designed for the detection of grain imperfections, with accurate performance, stable work, efficient operation, 4 minutes to complete the test, and the test results are equivalent to the level of senior quality inspectors.

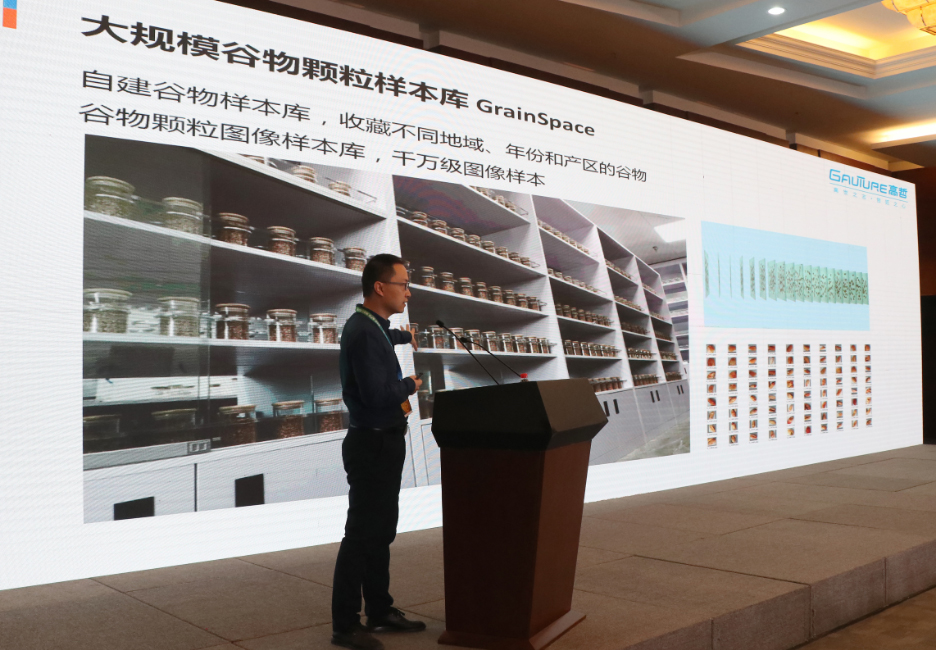

GauTure AI fast tester has innovatively introduced deep learning technology in the field of grain quality inspection, and based on machine vision and deep learning technology, it has developed the core key technology for imperfect grain detection, i.e., GrainNet, a deep neural network for grain detection and identification, in addition to constructing a large-scale grain image database GrainSpace, and utilizing the support of big data to train GrainNet deep network, thus developing an automated detection algorithm with accurate detection capability, which not only saves manpower and shortens detection time, but also improves the objectivity of imperfect grain detection. In addition, a large-scale particle image database, GrainSpace, was constructed, and the GrainNet deep network was trained using big data support, thus developing an imperfect particle detection algorithm with accurate detection capability and realizing the automated detection of imperfect particles, which not only saves manpower and shortens the detection time, but also improves the objectivity, high efficiency, and accuracy of the detection of imperfect particles.

Dr. George Liang introduces GauTure AI Quick Checker to the guests.

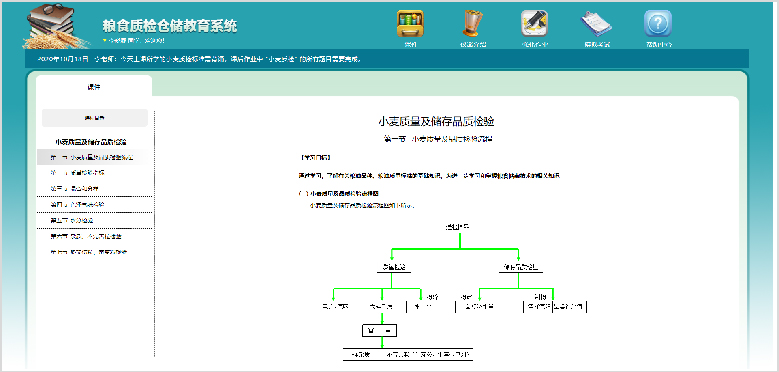

In addition to the fast tester, GauTure has also established a basic sample library for the grain industry, covering multiple varieties, geographic regions, years, and types of testing, laying the data foundation for the intelligent development of the grain industry, and its independently researched and developed "Grain Quality Inspection and Warehousing Education System" is designed to utilize the new technology to enhance the training efficiency and professional competence of the quality inspectors.

Grain quality control and warehousing education system

In the future, GauTure will continue to focus on the research and product development of quality testing and analytical instruments and related information management systems in the field of grain and agriculture, and utilize artificial intelligence and big data technology to assist in the intelligence and automation of grain quality inspection.